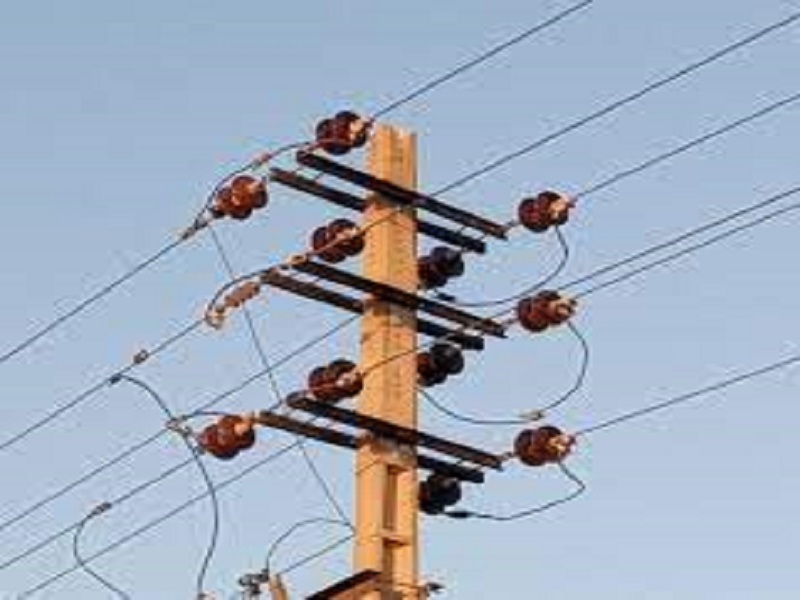

What is a pin-type insulator?

Pin insulators have a fundamental importance in keeping the rule that

transmission lines need a distance apart from each other by supporting towers help. They are mainly used in power distribution systems with a voltage of 33kV.

An insulator that isolates a wire from a physical support, such as a pin on a utility pole or tower, is referred to as a pin type insulator. It is organized on a pin, as the name implies, and linked to a conductor. The conductor is held in place by grooves on the top of the pin insulator.

Depending on the voltage of application, these insulators are available in various parts, such as a single part, a two-part, or a three-part type. In pin insulators, non-conducting materials like porcelain, ceramic, silicon rubber, polymer, etc. are integrated.

This article is written with a clear objective to explain how pin-type insulators work, their causes, considerations to design pin insulators, their advantages and disadvantages, and other relevant facts.

How do pin-type insulators work?

Pin-type insulators consist of porcelain material, they are mounted on a galvanized steel pin which gets fixed with the pole’s cross arm. The line conductor can be kept in the groove on the insulator’s upper end. Electric current sometimes flows across the surface of the insulator. In order to function, they insulate the line conductor from the metal tower. The conductor is tied with the groove, wrapping with the same wire as the conductor.

An insulator loses some strength when it becomes wet because outside its surface conducts electricity. An insulator features an umbrella-like form to shield the lowest portion from the elements. The insulator is encircled by ridges called “rain sheds” to keep the interior side dry.

Causes and consequences of poor insulators

It is equally essential that insulators are designed in such a manner that overcomes the electrical and mechanical stress on them. Electrical stress on the insulator depends upon the line voltage.

The failure that comes in the insulators is caused either by a puncture or flashover. Puncture in the insulator occurs due to electrical discharge between conductor and body of the insulator through its pin. It may be caused in the insulator due to moisture or dirt particles depositing in the insulating material. As a result, a small leakage current begins to flow. When such a puncture occurs, the insulator gets damaged permanently.

By creating an arc between pin of an insulator and the line conductor, it is possible to trigger the flashover of an insulator due to an electrical discharge. In most cases, instantaneous flashover happens after lightning strikes and switching surges. Flashover may occur due to an abrupt increase of the voltage (voltage transient) since it exceeds the high voltage handling capacity of the insulator. Therefore, it is the result of the insulator’s electrical loss.

The flashover does not damage the insulator, but the perforation makes it worthless. The insulator gives the material enough thickness to prevent a surging perforation. By strengthening the leakage resistance, the flashover is reduced to a minimum. The leakage path length is extended by adding more layers, or “petticoat.”

Different types of electrical insulators

Each of these insulators, which are utilized in transmission and distribution systems, is made up of numerous insulating discs. Based on their ratings, these are divided into many types, which include the following.

- Pin Insulator

- Suspension Insulator

- Strain Insulator

- Shackle Insulator

- Post-Insulator

- Stay Insulator

- Disc Insulator

Pin-insulator

Distribution systems use this kind of insulators. This insulator can tolerate voltages of 11 kV. It is made of a material with high mechanical strength.

Suspension Insulator

A suspension insulator is also called a disc insulator. Materials like porcelain or glass can be used to design these insulators. The suspension insulator solves difficulties like operating on high transmission lines above 33kVs. The suspension insulator consists of a string of insulators connected in series, with the lowest insulator serving as the line conductor.

Strain Insulator

When the suspension string is applied to support a very high tensile load on the conductor, the strain insulator is given its name. Due to the fact that it is utilized in an overhead transmission system, it is related to suspension-type insulators. However, its requirements and output differ somewhat. The strain insulator can withstand 33 kV of electricity. These insulators are situated in isolated positions, probably in the transmission line.

Shackle Insulator

One of the best insulators is the shackle, which is formed of high-quality porcelain materials. Although small in size, these insulators are utilized in overhead distribution systems. A metallic strip can be used to join this insulator. This insulator has a 33 kV voltage capacity and can be used in bend or circular turn locations.

Post-Insulator

Post-type insulators are best suited for devices with greater voltages, like pin insulators. These insulators are utilized in substations for their suitability for various voltage levels. It is positioned vertically to safeguard transformers, switchgear, and other connecting parts. It is also taller in size. The post insulator is larger and has more petticoats than pin insulators.

Stay Insulator

The wire’s insulator, known as a porcelain stay insulator, is used to keep objects from falling to the ground. The distribution lines make use of these rectangular insulators. These are smaller compared to other types. The stay insulators are elevated above the ground to accommodate low voltage cables. The stay insulator is usually elevated above the ground.

Disc Insulator

Disc insulators offer an affordable and premium raw material substitute for medium and moderate pollution levels. In the market, these insulators are well-liked for use in transmission and distribution lines and industrial use. They have different high-efficiency features like minor corrosion, sturdy design, and many more.

What to consider while designing pin insulators?

When constructing a pin insulator, an engineer must take the following factors into account.

- The wire is fastened to the insulator’s top. The insulator’s base can then be connected to maintain the earth’s potential structure.

- The insulator must put up with any potential friction between the conductor and the earth. “flashover distance” refers to the separation between the conductor and the earth.

- The upper insulator is constructed to resemble an umbrella, shielding the interior components from the elements. Insulators must be made to shorten the distance between flashovers since the top face of the top petticoat is prone to keep the maximum flashover voltage while it is raining.

Do you want to know some amazing facts about ‘Federal Pacific Electric Panels’, read this article in our ‘Technology’ category: Federal Pacific Electric Panel: Everything You Need To Know About What Causes The Federal Pacific’s Electric Panels To Fail?

Advantages of pin-type insulators

There are various advantages of using a pin types insulator, which are;

- This insulator has a significant mechanical strength.

- It costs very little.

- A reasonable creepage distance is present.

- One can use pin-type insulators with a high-voltage transmission line.

- This insulator’s construction is straightforward.

- Pin type insulators are simple to maintain.

- A pin type insulator can be used in both horizontal and vertical positions in the transmission lines.

Disadvantages of pin-type insulators

Following are some of the cons (disadvantages) while using pin-type insulators.

- It only applies to the utilization of transmission lines.

- The spindle has to be used.

- Pin-insulators are limited to using up to 36kV of voltage.

- The thread of an insulator could be damaged by the insulator pin.

- These insulators will become expensive and bulky for voltages beyond 50KV.

- Insulator pins sometimes damage the insulator head.

Final Thoughts

Pin insulators are, of course, an excellent option to use in low low-voltages transmission lines. The main purpose of the insulator is to keep the cable or wire separate from the structure that holds the wiring in place. So this article provides an overview of pin-type insulators covering their advantages and disadvantages with other interesting facts in detail. Choose the appropriate insulator type by analyzing the transmission lines’ requirements.

Apart from this, if you are interested to know more about Breaker Tripped then visit our TECH category.